91L Lab Grade Explosion-Proof Precision Oven

Technical Features:

|

Dimensions (mm)

|

Width

|

Height

|

Depth

|

|

Internal

|

450

|

450

|

450

|

|

External

|

1450

|

1720

|

1350

|

Temperature range: RT℃+ 15℃ to +200℃

Temperature uniformity: ≤±2.0℃

Temperature fluctuation: ≤±0.5℃

Temperature deviation: ≤±2.0℃

Heating Rate: RT + 15℃ → 200℃ (Non-linear, No-Load, Approx. 5℃/min)

Note: it adopts natural cooling with no rapid temperature reduction function.

Other parameters

Power supply specification: AC 220v, 50/60hz, 1∮3 wires

Rated current: AC 25A, power 5.5KW

Industrial 91L Explosion-Proof Precision Oven

Technical Specifications

- Door structure: Adopting a hinge-type single-door design (handle on the right, hinge on the left when facing the oven) for easy operation; sealed with environmentally friendly silicone rubber gaskets and fitted with cylindrical handles.

- Explosion-proof design: Perimeter reinforced with explosion-proof door hinges, three-layer tempered glass window, explosion-proof fence, effectively safeguarding test operation safety.

- Inner chamber material: SUS#304 stainless steel plate—corrosion-resistant and easy to clean.

- Outer casing material: rust-proof steel plate with surface spray coating—sturdy and uniformly aesthetic.

- Control system: Q8 touch screen controller for intuitive operation and precise parameter setting.

- Heating & air circulation: Equipped with a double-layer convection system to ensure uniform temperature distribution throughout the chamber.

- Communication function: Standard USB interface (for curve & data download); standard LAN port; native support for network control communication protocols and PC upper computer control software.

- Status indicator: Three-color signal lights for real-time display of equipment operation status and fault alerts.

- Test holes: One 50mm-diameter hole on each side, with 2 silicone plugs included; supports external power access for on-site product testing.

- Mobility & stability: Fitted with 4 adjustable casters for stable placement and convenient movement.

- Shelves & load capacity: With central column support; 4 shelves on each side (left/right) when the door is open; single shelf load capacity ≤20kg.

- Pressure relief & battery test: Configured with pressure relief port and automatic pressure exhaust device (opens on pressure rise); matched with external charge-discharge test cabinet for battery overcharge & over-discharge tests.

91L High Precision Explosion-Proof Oven

-

-

-

Communication Functions

An optional mobile app control module enables real-time remote monitoring and operation of the oven. Users can track core parameters (e.g., temperature, operating status) in real time, send control commands, and view historical data curves via the app, greatly enhancing operational convenience and management efficiency.

Test Holes

Standard configuration includes one φ50mm test hole on each side, fitted with silicone plugs for airtight sealing. The quantity, size and layout of test holes are fully customizable and scalable to meet customers’ actual testing needs. Please specify your requirements in the order to ensure seamless integration with your testing processes and associated equipment.

Customization Services

We offer flexible and comprehensive customization services to meet the diverse demands of different industrial applications. Beyond standard specifications, key technical parameters (e.g., chamber dimensions, temperature range, heating rate, shelf load capacity and control system functions) can all be adjusted according to customer requirements. Our professional R&D and engineering team provides one-stop customization solutions covering the entire process from scheme design, prototyping to production and commissioning, ensuring the equipment fully aligns with your workflows and testing standards.

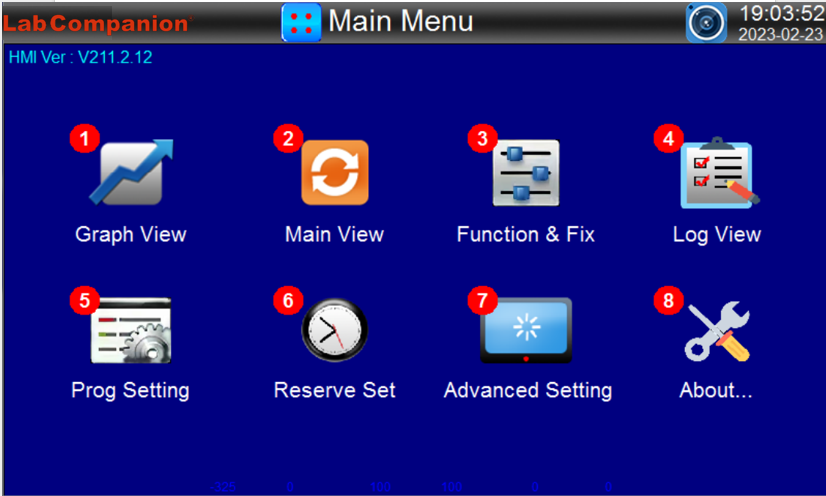

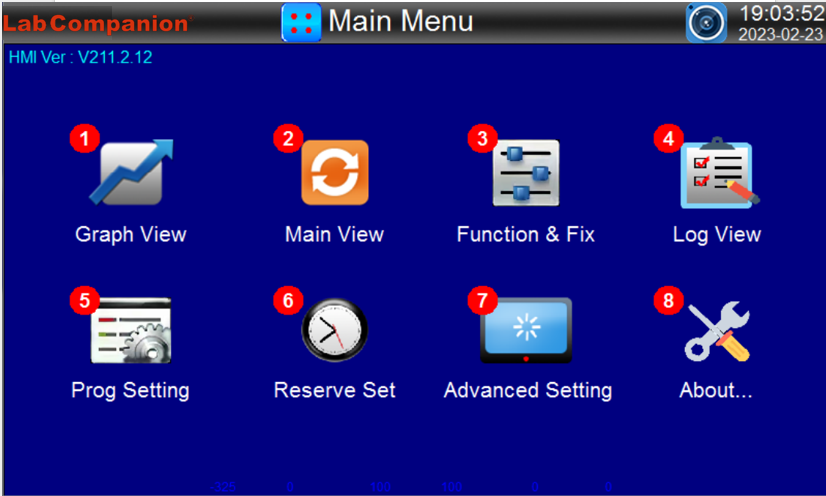

Premium 91L Explosion-Proof Precision Oven

|

NUMBER

|

Indication Content

|

Content Description

|

|

①

|

Graph View

|

Move to the program curve view,history curve

and setting screen.

|

|

②

|

Main View

|

Move to the fixed value/program control screen.

|

|

③

|

Function & Fix

|

Move to the additional function and operation

mode setting screen.

|

|

④

|

Log View

|

Move to the operation record view screen.

|

|

⑤

|

Prog Setting

|

Move to the group setting menu screen.

|

|

⑥

|

Reserve Set

|

Move to the current time and scheduled running time setting screen.

|

|

⑦

|

Advanced Setting

|

Move to the menu screen of file backup,communication setting,manual debugging, fault recording and screen capture browsing.

|

|

⑧

|

About...

|

Move to the screen for viewing user information

and current touch screen system status.

|